Carbon fibre: what is it? which is its use?

Why it is a special material?

Let’s start with carbon

To produce carbon fiber, Carbon is needed. It is a chemical element with an atomic number equal to 6, meaning its atom has 6 protons and 6 electrons. The most common isotope has a mass equal to 12 UMA, i.e. its nucleus contains 6 neutrons. In nature, it can be found in two pure forms: graphite and diamond. In combination with other chemical elements, it can be largely found in the form of carbon dioxide or calcareous rocks, among others. Moreover, carbon is the basis of organic chemistry, meaning it is the base element for the chemistry of living organisms.

Diamond and Graphite: differences

Diamond is one of the crystalline forms in which pure carbon can be found. It is a material with high hardness and a specific weight of 3.51 g/cm3, with very little dilation coefficient and with low atomic heat value (product of heat times atomic weight). Diamond can withstand unaltered until temperature reaches 2000 °C, and it does not react with common reagents at room temperature. It behaves as an insulation material with respect to electric and heat transmission.

Graphite is the second crystalline form in which carbon can be found in nature. It is found in the form of clusters or thin layers (more or less affected by earthy matters), and it is very tender (its name comes from the Greek word grafo “to write”, referring clearly to its use for writing on paper). It has a specific weight of 2.22 g/cm3, and its atomic heat is a bit higher compared to that of a diamond. Differently from diamond, graphite has a quite high electrical conductivity, that increases with increasing temperature.

How are carbon fiber composites made?

Carbon fiber composite components (the material is also known as CFRP, Carbon Fiber Reinforced Polymer) have two main components: the carbon fibre, i.e. the structural material responsible for the mechanical properties of the artefact, and the resin, which acts as a matrix in which the carbon fibre strands are immersed, and it is responsible for their cohesion. The resulting composite material has excellent mechanical characteristics (coming from the carbon fibre) and low weight.

To produce carbon fibres, organic long-chain molecules of different types, after being transformed into thin strands, go through a complex oxidation process under an inert atmosphere, at temperatures up to 2000 °C. The consequence of such conditions is the onset of a chain of chemical reactions, known as graphitisation, that results in the removal of mostly all the atoms different from carbon. The organic molecules are therefore transformed into graphite (carbon at 92%-96%). The graphitised organic chains finally fold themselves generating a large number of carbon strands with excellent mechanical properties.

Since when materials made with carbon fiber are used?

Carbon fibre composites were first produced during the 50s, but the first commercialisation of carbon fibre-based products came only

after a few decades. Given its characteristics (excellent stiffness and lightness), carbon fibre composites became the perfect substitute for metallic materials. Its specific weight is in the range of 1.5-1.8 g/cm3, i.e. approximately one-quarter of the irons and half of the aluminium. Reglass is able to manufacture carbon fiber composites having a wide range of elastic moduli, between 80 GPa (similar to the aluminium modulus) and about 350 GPa (i.e. quite higher modulus than steel).

Uses

In the last 40 years, Reglass used carbon fibre composites to realise high-performance artefacts and components. Reglass technologies and know-how allowed the company to become a leader in several applications in the sportive field, such as high-performance fishing rods and special windsurf masts. The company also served a number of different customers in different sectors, manufacturing satellite parts, and accessories for the automotive and nautical sectors (see the yaw for the catamaran Luna Rossa). Recently, applications for earthquake-proof systems have been developed with the realization of the Sismocell system.

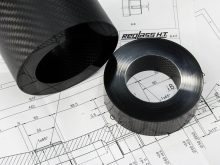

Carbon fibre composite rollers are successfully adopted in several industrial applications, such as aluminium, film and paper converting machines, as well as in flexographic printing machines. In all these sectors, the growing needs in terms of productivity and product quality result in the need for faster and more stable machines. Carbon fibre rollers, with their unique characteristics in terms of lightness and stiffness, are able to fulfil the needs of the most advanced machines. Reglass build its rollers using the Wrapping technology, to achieve the best performances and maximum product customisation. The process is based on the application of a sequence of PrePreg sheets (carbon fibre accurately impregnated with resin) on moulds, in the way to maximise the roller’s mechanical performance according to the customer’s needs.

Product for the flexographic printing and for converting:

- Cliché rollers, sleeve mandrels, anilox-sleeve mandrels

- Rollers for plastic film converting, tissue paper converting and nonwoven fabric production

- Pneumatic shafts

Gallery