Flexographic printing

Flexographic printing

Flexographic printing (more commonly called flexo) is a direct printing method that uses a printing plate made of rubber or photopolymers (also known as flexographic plates or cliché) to transfer the ink to the support to be printed. Flexo printing was initially used only for the printing of packaging, while today is also used for other applications such as journals. The raised areas in the printing plate are responsible for the ink transfer, while the recessed areas correspond to non-printed areas. The printing plate is flexible and soft, and it rolls up on a mandrel. The printing is direct: the material to be printed is pressed between a back-pressure cylinder and the mandrel where the printing plate is rolled up: in this way, the ink deposited on the raised areas of the printing plate is directly transferred to the support.

Characteristics

Strengths of flexo printing are the relatively low cost of the flexographic plates, the possibility to mount the printing plates on the mandrels in ancillary equipment, the easiness and velocity of work change, the possibility to print on many different supports in terms of thickness and superficial finish, the printing machine simplicity and relatively low cost, the possibility to use cheap and fast-drying inks. The number and types of materials printable through flexography machines are vast, including materials with a rough surface and not reflecting materials like corrugated cardboard.

The products

The most widespread application of flexo printing is related to converting plastic film for food packaging. Thanks to its characteristics the flexographic process is particularly apt for printing on metal and plastic film like PET, PE, and aluminium.

This typology of the printing process largely increased during the last 30 years, thanks to the increasing importance of large-scale distribution. Flexography is largely used for the printing of milk containers, drinks, shopping sachets, gift paper, and wallpaper.

Distribution of the flexographic printing market.

- Flexible packaging 26%

- Corrugated cardboard 21%

- Plastic bags 10%

- Drinks cans 8%

- Paper sachets 8%

- labels 5%

- gift paper 4%

- wallpaper 3%

- others 15%

The ink system

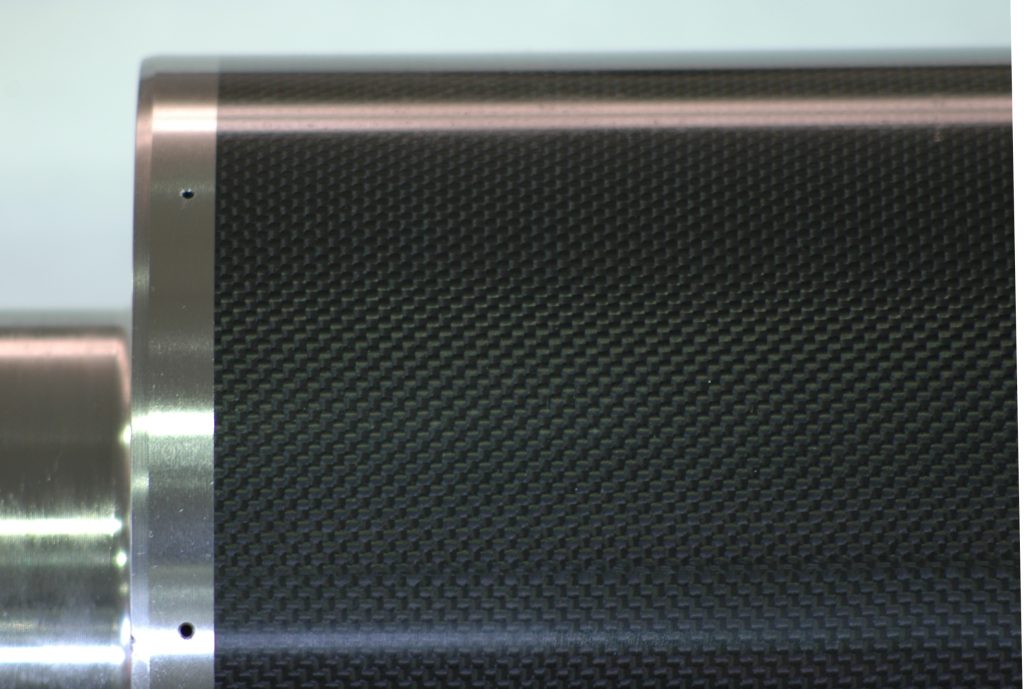

The ink is applied on the flexographic plate through an Anilox roll made of steel, aluminium or carbon fibre composite, covered by a finely engraved ceramic layer. The engraving of the anilox surface is aimed at creating a large number of small cells, each one able to pick up a defined quantity of ink and discard the ink to the printing plate once in contact. The Anilox roll can be charged with ink through two different systems. The first one uses an inkwell (open or closed room) coupled with a doctor blade that removes the excess ink from the anilox surface. The second system adopts a rubber roller to pick the ink from a basin and transfer it to the anilox roller. The rubber roller rotates at a slightly smaller velocity than the anilox roller, so removing the excess ink from anilox cells while delivering the ink.

The Anilox cylinder can be engraved with cells of different shapes and depths, thus resulting in different superficial cell densities, between 80 to 800 cells/cm2. A greater number of cells guarantees the printing of smaller details, while a lower number is preferred when printing flat-colour backgrounds.

Types of machines

The flexographic machines can be produced in three different structures: inline, planetary (or central drum) and stack (independent cylinders). The first two versions normally print on one side only, while the stack version allows printing, with more combinations, on both sides of the support.

- The in-line presses present a series of separate in-line printing elements, one for each colour, with drying caps between one element and the other.

- The planetary or satellite presses use a single large central cylinder to press the support on the clichés, which are therefore placed around the central drum (since the name of the machine type). This technique lowers the material deformation and allows printing on thin or deformable materials with good precision.

- The stack presses are very much similar to the planetary ones, but instead of a single central cylinder, they have an individual back-pressure cylinder for each printing unit.

Reglass and the flexographic printing

Reglass offers a vast choice of carbon fibre composite mandrels and rollers for flexographic printing.

The company, thanks to the advanced technologies and the accurate work by its researchers, offers high-performance rollers and cylinders for flexographic printing. The company works in synergy with universities and scientific institutions and closely collaborates with resin and fibre suppliers to obtain high-quality carbon pre-pregs to achieve the best quality in its finished products. The flexographic printing sector is one of the most technically engaging, given the high mechanical performances required to the mandrels to obtain good printing quality and high productivity.

The company has long been a leader in carbon fibre processing techniques, initially used in the construction of competition fishing rods. It was the first company to introduce the Sheet wrapping technique in the sports sector, importing the best carbon fibres from Japan. Through this production process, the Prepreg carbon fibre sheet is applied in various directions to maximize the structural efficiency of the product.

From fishing rods to rollers for flexographic printing: it is possible to replace the cliché-holder cylinders and the metal anilox cylinders, with carbon cylinders to significantly increase the speed and printing performances. The carbon fibre rollers are light and guarantee excellent mechanical performance, allowing to increase the productivity of the machines on which they are installed. The use of carbon fibre cylinders also allows to generally improve the performance of the machine: more precision, definition, greater colour clarity.

In the field of flexographic and tissue printing products, Reglass provides devices with CE certification.

Reglass and digital printing

Digital printing is a generic term to identify a printing system where the shape to be printed is generated through electronic processes and directly printed on the support to be printed. Among the different digital printing techniques, the most widespread are laser printers and inkjet printers.

Laser printers: this technology is used on office laser printers, classic copiers, and colour laser copiers. These machines are based on an electrostatic roller, that can be locally charged only in the areas where the supply of ink is necessary. The toner powder is attracted to the charged areas of the roller and then transferred to the paper. Very large and fast laser printers for printing large quantities of documents with variable data (bills, invoices, bank statements) are now widespread.

The inkjet machines use a printing head able to release very small quantities of ink directly on the support drawing it from special tanks. Each droplet released is a point of the image to be printed. The printing head generally travels by different methods on the support to be printed. This technology is based great part of the table printers for small formats (A4 or A3) or plotters for printing large formats (up to 6 meters in the width of the roller). The use of inkjet machines is widespread in digital printing centres and is expanding to stationery stores and printers.

In the industrial printing (roll-to-roll) sector, digital printing machines generally use a geometry similar to that of an in-line flexographic machine, in which each printing unit (which in flexography includes the distribution of ink, the anilox roller, the plate-holding cylinder, and the counter-pressure roller) is replaced by an inkjet print head.

These machines, with performances now similar to those of flexographic machines, allow printing on reels of a width exceeding 1300 mm, at speeds above 150 m / min. In these machines, there are no sleeve holder cylinders, but extremely light and performance rollers are needed, which Reglass is already developing thanks to its technology and experience.