Carbon fibre and Reglass technology

Carbon fibre working process

The process starts with Carbon fibre: it is processed with epoxy resins until a pre-impregnated material – called prepreg – is obtained, then it is cut into sheets of carbon fibre which, through the Sheet wrapping technology, are used for various types of applications of different use from industry, to sport, to construction.

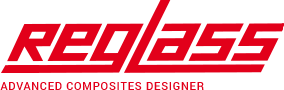

Raw material

Carbon fibre is a threadlike structured material constituted by chains of carbon atoms that is used to produce a large diversity of composites, i.e. materials made of two or more components.

Features: high mechanical resistance, low density, a very low coefficient of thermic expansion, resistance to the effects of several chemical agents, and good fireproof properties.

Reglass uses carbon fibre with the best features and impregnates its with resins of its own formula. Carbon fibres are divided into two main categories.

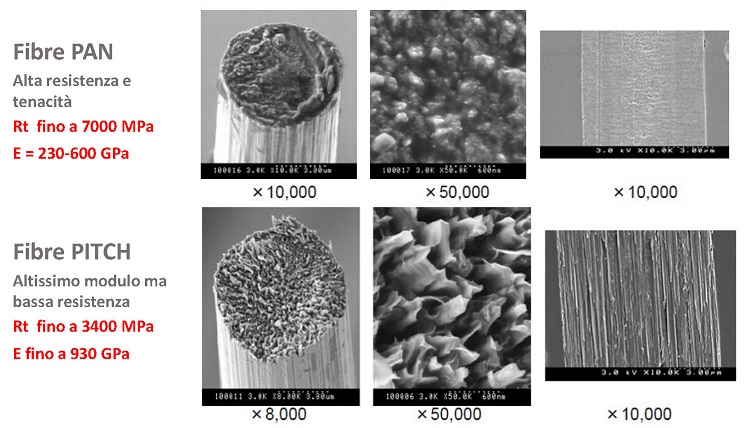

Prepreg, carbon fibre sheet

The process starts with the development of spools. The wires (yarn, composed of thousands of filaments) are flattened and joined up to form a carbon tape with unidirectional fibres. This then flows into an impregnating machine that makes the epoxy resin penetrate. The Prepreg is then wrapped in coils that can be stored in refrigerators at temperatures of -18° C.

Reglass has outlined a particular knowledge to assure a deep impregnation of the carbon fibres from the epoxy matrix, while guaranteeing at the same time an excellent precision in the fibre/resin relation (between 2-3%).

Thanks to this exclusive Prepreg technology, it is possible to produce thin layers with a perfect distribution of tension. The weight, the inertia and the thickness are reduced and therefore the relation between those factors is optimal. It’s the best offered on the market.

The result: great homogeneous behaviour of the product that has to be created, and an excellent correlation between project data theories and those detected on piece.

Sheet wrapping, a sheet winding process

Carbon fibre prepreg is cut into sheets depending on the tubular project that has to be manufactured. The obtained pieces are then wrapped (Sheet wrapping) onto a mould, making up the next layers for wrapping.

The use of the one-directional Prepreg permits the application of fibres in various directions in a way so as to maximize their structural efficiency. After that comes the polymerization in an autoclave, which increments the quality and the mechanical features of the product as it avoids the possible empty zones, so the material becomes compact.

Reglass can then use the particular prepregs with carbon fabric. They are then used especially at the external part of the roller to protect the underlying layers.

The Nanotechnologies and composite products

Nanolith is an innovative technology based on the use of nanomaterials and developed by the Reglass laboratories. Since 2008 it has been introduced in the production of fishing rods.

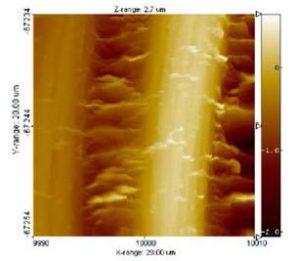

The nanoparticles are united on an anatomic and molecular level with the carbon fibres and the resin’s superficies. The connection that is created and that is generated through fibre-nanolith-resin, is able to dissipate the vibratory energy and enormously increase the breaking load. In fact, there are internal scrollings that are much more accentuated as compared to the ones of a classical composite. The features of the stiffness do in fact remain equal, due to the very high elastic modulus of the used carbon fibre.